Using simulation to

optimize the real world

Around 40 percent of global carbon emissions are accounted for by buildings. Yannick Renaud and his Sustainability & Simulation team at TÜV SÜD in Hamburg have taken up the challenge of making building operation a more climate-friendly affair. To do so they use digital twins––virtual building replicas enabling real-life characteristics of the buildings to be simulated and optimized.

Mr. Renaud, can you explain what a digital twin is?

Renaud In very general terms, a digital twin is a virtual model that replicates real estate properties or processes in varying levels of detail. They are very frequently used to create virtual buildings, digital replicas of existing or planned buildings which generate information and findings that can then be applied in the real-life buildings. Digital twins are a completely transparent method of identifying potential areas for optimizing sustainability on behalf of our clients. They are also the basis of BIM, or Building Information Modeling, a digital building planning and construction method that is becoming increasingly popular.

Yannik Renaud has been with TÜV SÜD since 2017 as a project engineer for simulation and energy technology in the real estate sector. A specialist in flow simulation, he has performed wide-ranging analyses from skyscrapers many hundreds of meters high to green corridors for large-scale urban residential districts. He has been Head of Sustainability & Simulation at the TÜV SÜD subsidiary TÜV SÜD Advimo since 2021.

It all sounds rather theoretical. How can your clients benefit from a digital twin in concrete terms?

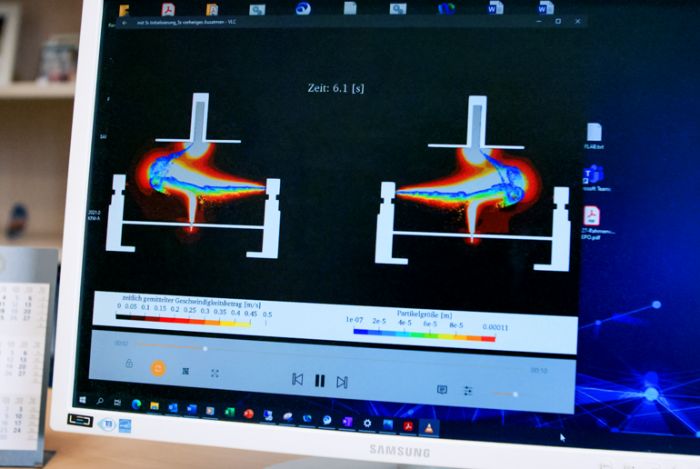

Renaud Two very concrete areas where digital twins are used are energy and building physics consulting. Our team specializes in thermal flow and air flow simulation. The digital twin software allows us to modify parameters at will and simulate situations to determine, say, the necessary dimensions for a heating system or improvements to building ventilation. For example, we were able to provide support during the COVID-19 pandemic by evaluating air quality in rooms and spaces. Overall, our work thus contributes to enhancing the efficiency of buildings, and thus pays into climate protection and sustainability, but also helps to create spaces where people enjoy living and working.

Does the size or type of building have a role to play?

Renaud No. The technology can be used for cross-sectoral cases such as industrial plants. Scale is also not an issue. Our simulations can be produced to micron-level accuracy, or replicate entire city districts.

Does this mean that in the future we will rely more on virtual worlds than real-life experience?

Renaud No. Our real-life expertise is exactly what enables us to create valid and accurate digital twins. At TÜV SÜD, we have over 150 years of know-how to draw on. As a result, we have in-depth familiarity with how real buildings and industrial plants work. Our strength lies in our ability to bring together our experiences from the real and digital worlds and merge these two worlds. By using the digital twin method, we are making an important contribution to enhancing building sustainability by ensuring plants are correctly dimensioned and energy efficiency is optimized.